Classification:Company News Release time:2021-09-09 611

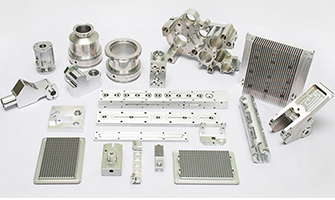

Precision machining is no longer just a simple form of machining. At the moment of seamless connection with high technology, it can better play its role, especially in the digitization of machining industry, which has made a qualitative leap in its development and can better serve industrial development.

Machining features of precision mechanical parts:

1. Machining of precision mechanical parts

When the machining precision of precision parts is nano or even atomic units, the machining of ultra-fine parts can not comply with it. It is necessary to use the method of special precision parts machining, that is, the application of chemical energy, electrochemical energy, thermal energy or electric energy. Make these energies exceed the binding energy between atoms, so as to remove the adhesion, bonding or lattice deformation between local atoms on the workpiece surface, so as to achieve the purpose of ultra precision machining. These processes include mechanochemical polishing, ion sputtering and ion implantation, electron beam exposure, laser beam processing, metal evaporation and molecular beam epitaxy.

2. Machining of precision mechanical parts

It mainly includes precision turning, mirror grinding and grinding. Micro turning is carried out with precision ground single crystal diamond turning tool on precision lathe, and the cutting thickness is only about 1 micron. It is often used to process spherical, aspherical and planar mirrors of non-ferrous materials with high precision and high brightness.

Prev:Solution to the roughening problem of copper precision parts

Next:No date