Classification:Industry Dynamics Release time:2021-09-09 160

At present, in the process of the development of China's machinery manufacturing industry, the demand for the precision and quality of parts processing is becoming more and more strict. In the process of precision parts processing, the influence of processing technology on the precision and quality of workpieces is very key. Therefore, we should carry out corresponding management and control on the machining process, so as to ensure the stability of machining and production, then analyze the influence of precision machining process on the machining accuracy of precision parts.

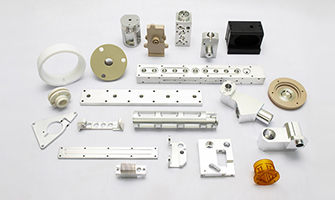

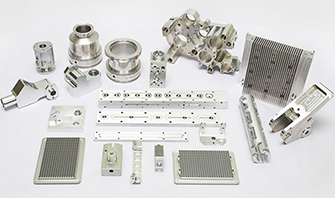

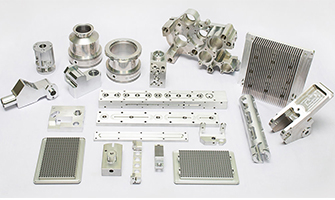

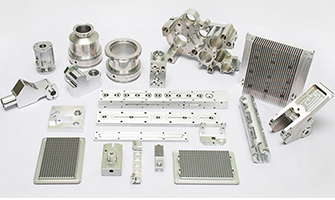

In the process of precision machining, strict requirements should be made for the quality of raw materials and semi-finished products used in processing and production. The processing quality of precision parts can be improved in the preparation of processing technology, the management of production and processing, and the application of precision mechanical equipment. In the process of formulating the processing route, the structural principle is generally observed: the benchmark first, and the processing stages are divided to ensure the quality of precision parts processing and the reasonable selection of mechanical equipment.

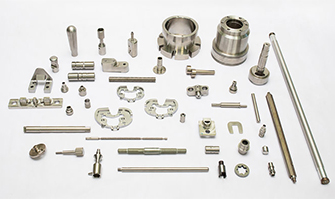

The requirement of precision machining accuracy is to control the machining error of parts within a certain range before machining. There are many factors leading to machining error in the process of precision machining.

The main points are as follows:

1. Collective error of process system

2. Principle error of processing method

3. Geometric error of machine tool

4. Adjustment error

5. Manufacturing errors of tools and Fixtures

6. Clamping error of workpiece and error caused by wear of process system

7. Error caused by thermal deformation of process system

8. Error caused by residual stress of workpiece

In the actual processing, scientific and reasonable processing technologies and methods can only be used within the tolerance range to reduce the errors in the processing as much as possible, so as to improve the accuracy and economic benefits in the machining process.